How to teach how to PCB?

These days, a useful quality to have is the endurance to weather the disinterested gaze—collimated through glasses thick and transparent as hockey pucks—of gathered young engineers listening with open mouths and a slightly hunched backs. It freaks me out that I now have a solid decade’s worth of practice doing this, thanks to leading and teaching proto-engineers since middle school, yet humbling to think that there are heroes who do this as a lifelong career.

The trick is to ignore the complete apathy and listless boredom your audience wears on their faces. That’s just how engineers show interest. Now that everyone has smartphones, a higher quality signal for your patrons’ fascination with you is noticing the low frequency by which they poke at Facebook.

Most recently, I’m proud to have taught a three-part workshop on printed circuit board (PCB) fabrication as part of the GT Invention Studio/Makers Club fall series. Among other records set this semester, this was the first time ever that the Invention Studio was inhabited by an electrical engineering majority*, when otherwise it comprises mechanical engineers with grease guns and crescent wren—UGGHRRR WOW THREADS SUCH METAL MUCH FEEDS & SPEEDS. It felt weird, but smelled better than anyone hoped for.

On top of attendance, reception to the PCB workshop was great. People had all pulled out their laptops with EAGLE already installed, as if they had read the emails I had sent out. I was surprised to hear that useful knowledge had diffused into the crowd.

The workshop was split over three days, and I had digital materials prepared for each one. The first and last sessions used Keynote presentations, while the in-between session had paper handouts. You can download these in PDF by clicking on them.

Day 1 §

Overview of hacking hardware and EAGLE demo. I used my interpretation of the Charles flavor of imparting knowledge—learning by facilitating projects. I disclosed my ideology and motivation, then deciphered jargon with a glossary, and finally provided a list of tools and vendors. At the end, I had everyone design a board on the spot.

Day 2 §

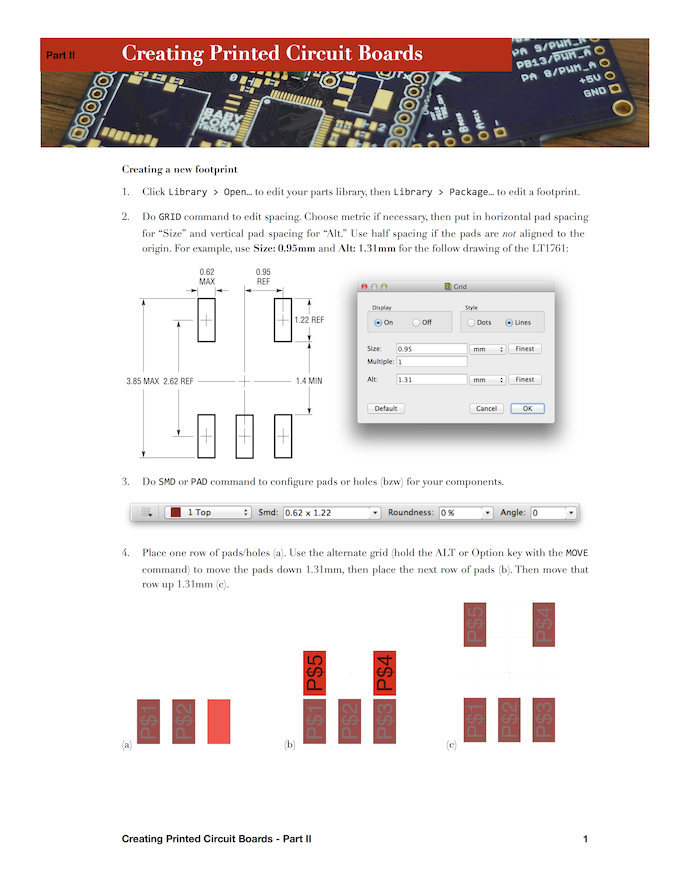

How to create custom parts in EAGLE. I snuck in some keyboard shortcuts and best practices talks in here. This is the tricky part of hands-on teaching: to pass on knowledge through osmosis by working next to each other. Normally this is while working on similar projects, but that’s difficult to replicate for the sake of a workshop.

Day 3 §

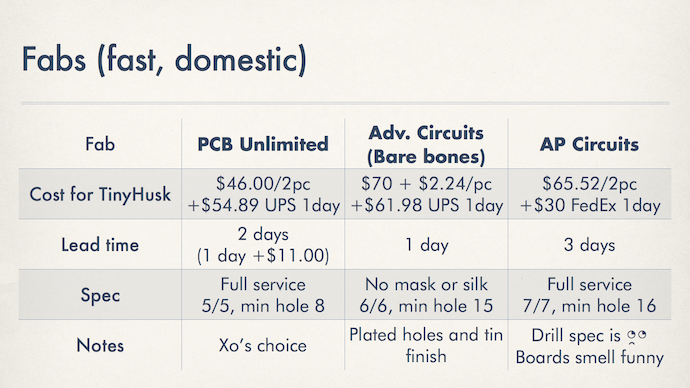

Where and how to make boards or get boards made. Since I was sick and this was during Dead Week, this became more of a round-table Q&A session than a lecture. However, this worked out to be a great “wrap” for the workshop and I was able to get a bit of feedback through it.

The slides I created for this session, however, are the most useful out of all the materials. The set contains tables of various PCB fabs that I’ve had some sort of experience with. They include poorly researched specs, lead times, and true costs† (setup fees, unit cost, shipping & handling) along with some anecdotal notes.

I was a bit shocked that everything had gone so smoothly. The pacing was especially important in the first session’s EAGLE demo. There, I put up each part I used and its library on the whiteboard, and secondly I had prepared EAGLE libraries and finished schematics/layouts to be shared on Dropbox.

The former meant everyone could follow regardless of their pace, and the latter meant I only needed to show EAGLE techniques once—after that, I’m free to pull out the neat, proofread design files like Rachel Ray pulls out chicken drumettes marinated overnight in lemon and soy sauce. In addition to minimizing Murphy’s Law demo mishaps, it also gave me the chance to take a breather, walk around, and do one-on-one’s with anyone having trouble.

Obviously, what also helps pacing is having a controlled number of focused, eager students. With a class of about 10 to 15, it wasn’t impossible to make sure everyone was following.

By the last session, people were bringing in their projects and devkits they had bought to play with. That was nifty! I’m incredibly fortunate to have had such an excellent audience. I’m super motivated to try this again, hopefully with improvements.